Abstract

Within the last century, coastal structures for infrastructure applications have traditionally been constructed with timber, structural steel, and/or steel-reinforced/prestressed concrete. Given asset owners’ desires for increased service-life; reduced maintenance, repair and rehabilitation; liability; resilience; and sustainability, it has become clear that traditional construction materials cannot reliably meet these challenges without periodic and costly intervention. Fiber-Reinforced Polymer (FRP) composites have been successfully utilized for durable bridge applications for several decades, demonstrating their ability to provide reduced maintenance costs, extend service life, and significantly increase design durability. This paper explores a representative sample of these applications, related specifically to internal reinforcement for concrete structures in both passive (RC) and pre-tensioned (PC) applications, and contrasts them with the time-dependent effect and cost of corrosion in transportation infrastructure. Recent development of authoritative design guidelines within the US and international engineering communities is summarized and a examples of RC/PC verses FRP-RC/PC presented to show the sustainable (economic and environmental) advantage of composite structures in the coastal environment.

Introduction

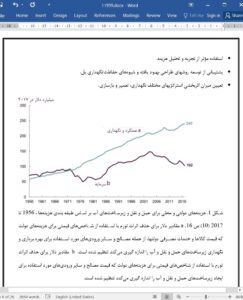

Within the last century, coastal structures for infrastructure applications have traditionally been constructed with timber, structural steel, and/or steel-reinforced/prestressed concrete. Given public infrastructure owners’ desire for increased service-life [1–3]; reduced maintenance, repair and rehabilitation liability [4, 5]; resilience [6]; and sustainability [7], it has become self-evident that traditional construction materials cannot reliably meet all these challenges for long-life coastal structures without periodic and often costly intervention ([8, 9] pp. 1–2). This observation is reinforced by the expanding gap between Operation and Maintenance expenditures, verses Capital investment for public infrastructure [10].

Conclusion

Over more than 30 years of field applications in bridge structures, FRP reinforcement has proved to be a reliable and durable material, able to fulfill the owners’ demand for increased service-life, reduced maintenance costs, resilience, and sustainability. Considering that almost 300 bridges have been completed using FRP reinforcement and prestressing in the US and Canada, there is substantial validation available for the structural engineering community. Embracing this cost-effective solution would avoid much of the ever-present risk of corrosion and future preservation efforts that are currently needed for coastal bridges and similarly exposed infrastructure. Additional comparative studies on contemporary structures using both LCC and LCA are important for holistically identifying the optimal economic and environmental solutions for sustainable designs.