Abstract

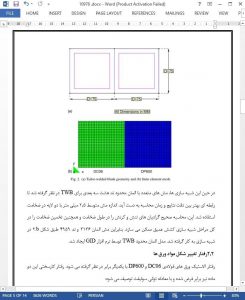

Tailor-welded blanks made of dissimilar, uniform or non-uniform thickness materials have potential applications in automobile industries. Compared to the base metal, the formability of tailor-welded blank is less due to the presence of weld area and strength mismatch between component blanks. Most sheet metals used to produce tailor-welded blanks have anisotropy induced during pre-processing stage due to large deformation. The orientation of the blank sheet rolling direction and the combination of the blank sheet materials has significant influence on the deformation behaviour. The effect of anisotropy in the tailor-welded blank and the orientation of blank sheets rolling direction during deep-drawing process are investigated in this study. Finite element analysis of deep-drawing mild steel and dual-phase steel tailor-welded blank models was carried out using research purpose FE code DD3IMP; to form a basis for tailor-welded blank design and development for a part. Anisotropy in the blank sheets has moderate influence and its contribution to increased material flow depends on the mechanical properties of the blank sheets. Appropriate combination of the blank sheets rolling direction orientation can significantly improve the formability of the tailor-welded blank in the deep-drawing of square cup.

1. Introduction

Environmental concern and fast depletion of fossil fuels have forced automobile manufacturers to implement strict government environmental regulations and to cater increased customer demands for improved fuel efficiency. Thus, the automobile industries are driven to look for high performance and light weight materials in order to improve the fuel efficiency, aesthetic and reduce the cost of the vehicle. One way of handling this issue is to increase the application of tailor-welded blanks in the automobile body parts. Through proper location of apt material in the automobile body by tailor-welding, the required functions of the body part can be accomplished at nominal cost. Tailorwelded blanks are produced from combination of materials brought together by employing advanced welding techniques, such as laser beam, mash-seam or electron beam welding. These techniques are intended to produce narrow weld-line with least heat-affected zone. Tailor-welded blanks thus produced with dissimilar and uniform or non-uniform thickness materials can be subjected to deformation to produce automobile components, such as body side panels, motor compartment rails, center pillar inner panels, wheelhouse/shock tower panels [1–4] and other market areas [5].

4. Conclusions

Numerical simulations were carried out to determine the effect of anisotropy and the rolling direction orientation of the blank sheets in tailor-welded blanks to form a basis for tailorwelded blank development for a part. In-house finite element code DD3IMP was used for the deep-drawing simulation of a mild steel and dual-phase steel tailor-welded blank. The simulations were performed without considering the presence of a weld zone between DC06 and DP600 sheet segments in the tailorwelded blank. The results of anisotropic tailor-welded blanks are compared with isotropic tailor-welded blank. The punch force required for deep-drawing increases with anisotropy in the blank sheets. The strength difference and the initial anisotropy induce uneven metal flow during deep-drawing. The top corner of the cup in mild steel sheet segment is subjected to largest plastic strains and yet does not lead to material failure until a draw depth of 35 mm for this geometry. Inadequate material flow to the bottom cup corner on the dual-phase side causes thinning. The weak material is subjected to large deformation and hence, the weld-line moves towards the stronger material side in the cup section and towards the weaker material side in the flange area. Significant contribution by anisotropic property is observed on mild steel segment in the tailor-welded blank. Thinning along the weld-line is more in isotropic material combination than anisotropic tailor-welded blank. Using appropriate combination of rolling direction orientation, and hence controlling anisotropy, significant improvement in the formability of tailor-welded blanks can be achieved.