Abstract

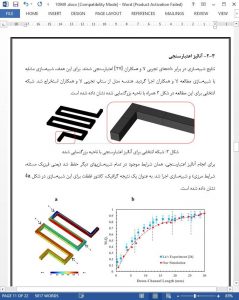

The Lab On a CD (LOCD), also known as Centrifugal Microfluidics, has evolved into a sophisticated platform for performing biomedical assays due to its marvelous miniaturization and accurate simulation of biological reactions. Among the numerous applications of the LOCD is fluid mixing. In this paper a centrifugal, serpentine micromixer is simulated and reformed toward better mixing performance. The micromixer was chosen to be curved as a curved design was found to be thrice as functional and compact as a rectilinear design, mixing-wise. The two angular velocity and opening radius parameters were originally hypothesized to affect mixing performance. Effect of angular velocity was studied over a broad range starting from quite low values. It was gathered that with increasing angular velocity, mixing performance initially drops and upon reaching a minimum at a threshold angular velocity, begins to continuously increase. The threshold angular velocity was found to be the spot at which the mixing regime changes from diffusion to secondary flow. It was also realized that increasing the opening radius enhances mixing performance only insignificantly, such that it would not be a practical means of making micromixers more efficient.

1. Introduction

The Lab-On-A-Chip (LOC) is a microfluidic miniaturization platform used in many chemical, biological and biomedical assays; e.g. the Point Of Care Testing (POCT) (Figeys and Pinto [1], Haeberle et al. [2], Lee and Choi [3], Chin et al. [4], Ryu et al. [5]). Because of its small dimensions, the amount of the consumed sample and reagent is significantly less than other known experimental platforms; i.e. nanoliters vs. milliliters, making the LOC extremely efficient concerning material expenses (Srinivasan et al. [6], Fair [7]). Several modules or operational units could be erected on the LOC for various applications in biological assays such as mixing, valving and separation (Strohmeier et al. [8]). The problem with the LOC is that each operational unit requires a separate micropump, mostly syringe pumps, as its driving force to operate. For this reason, multifunctional LOCs are rather scarce since employing several micropumps in an LOC complexes its design, making it harder to fabricate. To overcome the limitation on multifunctionality, the Lab-On-A-CD (LOCD) was introduced.

4. Conclusion

In this paper a centrifugal, serpentine micromixer was investigated along with modifications which enhanced mixing performance. The micromixer was given a curved design since it was realized that because of a strong Dean flow induced due to the curvature, the curved micromixer functions quite superiorly to a typical, rectilinear design. To put it quantitatively, the curved design reaches 90% M.Q. within 10 mm of down-channel length, whereas the equivalent rectilinear design reaches it in 30 mm. This means the curved design is three times as functional and compact, from a geometric design perspective. The effect of angular velocity of the LOCD on mixing performance was comprehensively studied.