Abstract

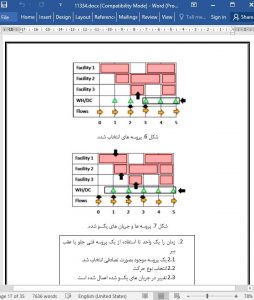

Supply Chains are complex networks that demand for decision supporting tools that can help the involved decision making process. Following this need the present paper studies the supply chain design and planning problem and proposes an optimization model to support the associated decisions. The proposed model is a Mixed Integer Linear Multi-objective Programming model, which is solved through a Simulated Annealing based multi-objective meta-heuristics algorithm – MBSA. The proposed algorithm defines the location and capacities of the supply chain entities (factories, warehouses and distribution centers) chooses the technologies to be installed in each production facility and defines the inventory profiles and material flows during the planning time horizon. Profit maximization and environmental impacts minimization are considered. The algorithm, MBSA, explores the feasible solution space using a new Local Search strategy with a Multi-Start mechanism. The performance of the proposed methodology is compared with an exact approach supported by a Pareto Frontier and as main conclusions it can be stated that the proposed algorithm proves to be very efficient when solving this type of complex problems. Several Key Performance Indicators are developed to validate the algorithm robustiveness and, in addition, the proposed approach is validated through the solution of several instances.

1. Introduction

Traditionally the design and planning of supply chain networks (SCN) has been undertaken based on individual concepts and applying only economic objectives, such as cost minimization or profit maximization. However, the increasing market competition, the customers’ change expectations, on the value of goods and services, combined with advances in technology and fast access to information demanded for an integrated view when managing supply-chain (SC) networks (Papageorgiou, 2009). In addition, the worldwide extension of business led to the availability of sets of alternative resources, as well as to a vast array of potential customers, justifying the current need of efficient SC management. Simultane ously, society has been developing an increasing level of awareness for environmental sustainability and companies have been realizing that economic objectives ought no longer to be the single concern of supply chains as environmental impacts resulting not only from their structures, but also from their operation need to be minimized (Seuring, 2013; Mota, Gomes, Carvalho, & Barbosa-Povoa, 2015). Dekker, Bloemhof, and Mallidis (2012) state that “Improving environmental quality comes at a cost, so the question is which trade-offs occur between the environmental impacts of an economic activity and its costs, and what are the best solutions for balancing ecological and economic concerns?”. This raises the concept of building ecoefficient solutions. Thus it becomes necessary to define an efficient integration of these SC main aspects when planning and designing SC so as to minimize environmental impacts while maximizing profit and responsiveness.

8. Conclusion

In this work a problem with increasing importance in the supply chain area has been addressed, the so called green supply chain design and planning. Economic but also environmental objectives are accounted when designing and planning supply chains aiming at establishing tradeoffs between the traditional profit objective and such systems environmental impact. Due to the recognized difficulties that arise when solving these problems through the most common published approaches, exact approaches, the present paper proposes an alternative solution approach based on a meta-heuristic that has proved to be promising and could consequently constitute thebase of an expert system application to support the decision makingprocess within such problems.