Abstract

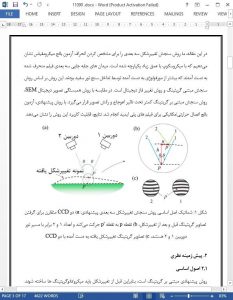

A micro-scale 3D deformation measurement method combined with optical microscope is proposed in this paper. The method is based on gratings and phase shifting algorithm. By recording the grating images before and after deformation from two symmetrical angles and calculating the phases of the grating patterns, the 3D deformation field of the specimen can be extracted from the phases of the grating patterns. The proposed method was applied to the micro-scale bulge test. A micro-scale thermal/mechanical coupling bulge-test apparatus matched with the super-depth microscope was exploited. With the gratings fabricated onto the film, the deformed morphology of the bulged film was measured reliably. The experimental results show that the proposed method and the exploited bulge-test apparatus can be used to characterize the thermal/mechanical properties of the films at micro-scale successfully.

1. Introduction

With increasing applications of thin films in many areas [1–4], the mechanical property characterization of thin films is crucial. Conventional applied methods, such as the wafer curvature method based on the Stoney’s formula and the nano-indentation method [5,6], have been applied to characterize the mechanical properties of the thin films. Although the wafer curvature method is easy to implement and applied to measure the residual stress of the films, it’s hard to extract other properties of the films. The nano-indentation test can be used to characterize the elastic-plastic properties of the film, but influences of substrates can’t be eliminated. So the above mentioned methods have limitations for the mechanical properties characterization of thin films.

To characterize the mechanical properties of free-standing films, micro-tensile test and bulge-test were developed. The micro-tensile test can measure the intrinsic properties of the films directly and constitutive behaviors with the increasing load applied [7].

5. Conclusions

A micro-scale 3D deformation measurement method based on gratings and the optical microscope is proposed and applied to the bulge-test to characterize the mechanical properties of the thin films. A microscale bulge-test apparatus was exploited. Thermal/mechanical coupling circumstance was incorporated in this bulge-test apparatus.

The error source and measurement accuracy of the proposed method is analyzed and estimated. The out-of-plane displacement accuracy is about 0.18 μm for the experiment conducted in this paper by the proposed method. It has been concluded that the accuracy of this method primarily depends on the grating frequency. It means the measurement accuracy increases with the increase of the grating frequency at the same deformation field.

With the proposed 3D deformation measurement method, the membrane bulge deflection was obtained. Combined with the bulge-test theory, the mechanical property of the film was evaluated. The polyimide films were tested at room temperature (25 °C) and 150 °C respectively.

The experimental results indicate that the elastic modulus of the polyimide films was reduced 27% at 150 °C compared with that at room temperature. The experimental results indicate that the proposed method is feasible for the bulge deflection measurement at micro-scale. It is also suggested that the method is promising in micro-scale 3D deformation measurement in other fields.