Abstract

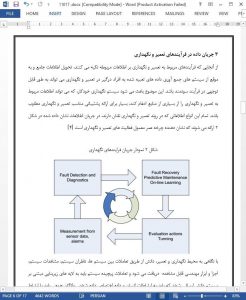

In recent years and across a myriad of industries, there has been a realisation that in order to optimise the Remaining Useful Life (RUL) of assets and to maintain optimal system level performance whilst assets age and at times with growing and dynamic loading demands, a transition to predictive maintenance from reactive and traditional condition based monitoring and maintenance is required to achieve return of investment (ROI) and performance targets. A sector driven by security and a need to defer investment within the asset base is the Energy sector. After a brief introduction to maintenance process's in the oil and gas domain, this paper presents a novel approach to hierarchical predictive maintenance of assets in through a distributed architecture, represented as domain knowledge-based system, that provides a viable solution for systems containing similar multiple assets.

1 Introduction

Year-round energy industry fields require the routine and permanent presence of a condition and performance monitoring (CPM) system [1], designed to maximise production uptime and asset availability. CPM systems respond to the asset manager’s need to continuously demonstrate ‘fitness for service’; and improve understanding of asset condition, which obviously support the decision making process for de-rating, process optimisation and scheduling for remediation and rectification task. Furthermore, there is also a requirement to provide enough evidence based knowledge to support the extension of the design life of components, and justifications tie with brown fields.

4 Conclusions

A novel approach to hierarchical predictive maintenance of assets in the oil and gas domain has been outlined. Through a distributed architecture, represented as domain knowledgebased system, it provides a viable solution for systems containing similar multiple assets. The domain model represents models of many aspects of the system (including a physical decomposition among others) and maps to Key Performance Indicators (KPI’s). The approach allows fault diagnosis from intelligent embedded tools to be performed at different levels within the oil and gas distributed system and the most appropriate modeling choices to be used for particular problems.