Abstract

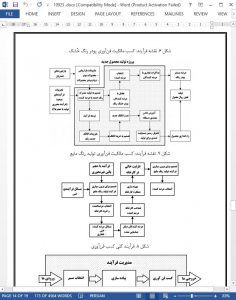

The effective management of technology as a source of competitive advantage is of vital importance for many organisations. It is necessary to understand, communicate and integrate technology strategy with marketing, financial, operations and human resource strategies. This is of particular importance when one considers the increasing cost, pace and complexity of technology developments, combined with shortening product life cycles. A fiveprocess model provides a framework within which technology management activities can be understood: identification, selection, acquisition, exploitation and protection. Based on this model, a technology management assessment procedure has been developed, using an ``action research'' approach. This paper presents an industrial case study describing the first full application of the procedure within a high-volume manufacturing business. The impact of applying the procedure is assessed in terms of benefits to the participating business, together with improvements to the assessment procedure itself, in the context of the action research framework.

Introduction

Background

The impact of technology as a source of competitive advantage for manufacturing industries is widely accepted by practitioners, governments and academics. In order to realise this competitive advantage, it is vital to understand both the specific technologies, and the ways in which organisations can best manage technology. These issues are of increasing importance as the pace of technology development and its complexity increase.

Industrial application

The assessment procedure (Phaal et al., 1998; Probert et al., 2000) has been applied 13 times in a total of 11 organisations during the development and testing phases (one example of which is described in this paper). The development phase was used to prototype procedure components and the testing phase to validate the integrated procedure. Industry sectors included: aerospace, automotive, electronic, electrical, marine, construction and pharmaceutical, including high-, medium- and low-technology organisations, with staff numbers ranging from about 20 to more than 5,000. In addition, the procedure has been applied within an independent academic organisation (i.e. a non-manufacturing service-based environment).

The procedure has subsequently been successfully applied on an independent basis, and has been recently published (Farrukh et al., 2000). The guide is designed for use by managers in industry and includes much of the tacit knowledge generated during its development and application in the form of process and facilitation guidance.