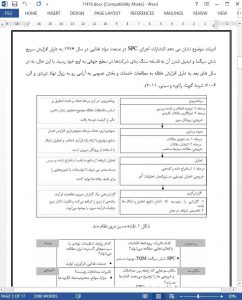

This paper is a systematic review of the literature on statistical process control (SPC) implementation in the food industry. Using systematic searches across three decades of publications, 41 journal articles were selected for the review. Key findings of the review include motivations: to reduce product defects and to follow the food law and regulations (benefits); barriers: high resistance to change and lack of sufficient statistical knowledge; and (limitations) an absence of statistical thinking and a dearth of SPC implementation guidelines. Further findings highlight the predominance of publications from the USA and the UK within this topic. Future research directions concerning SPC implementation issues as well as a ready reference of the SPC literature in the food manufacturing industry are also discussed.

1. Introduction

The fierce global competition in current businesses contributes to the growing popularity of continuous improvement practices. Despite being designated as the largest industry in the UK, the food industry’s performance (based on an assessment conducted against the European Business Excellence Model criteria) is lagging behind other industries such as the automotive, aerospace, and insurance (Dora, Van Goubergen, Kumar, Molnar, & Gellynck, 2013b; Mann, Adebanjo, & Kehoe, 1999). Food quality is not only related to the product alone, but also to the factors in production processes (Orr, 1999). Furthermore, quality control (QC), which is a crucial activity in the food manufacturing industry, which is commonly carried out by inspecting quality of final products, arguably fails and is ineffective to support continuous improvement efforts (Paiva, 2013).

7. Conclusions

The conclusions are based on the analysis of 41 articles concerning SPC implementation in the food industry published from 1980 to 2014. In particular, the trend implies that research and publications within this topic are dominated by studies from the UK and the USA. Generally, the review depicted that in the food industry, SPC was applied not only for QC and QI, but also for quality assurance purposes.