Abstract

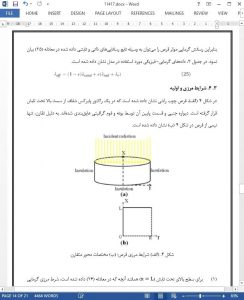

A two-dimensional, unsteady CFD (Computational Fluid Dynamics) single particle model was developed and used to simulate the solar pyrolysis process of beech wood pellets (10 mm in diameter and 5 mm in height). Pseudo-stoichiometric coefficients about the mass fraction of primary tar converted by the reaction into gas and secondary tar were determined at different temperatures and heating rates for the first time. The 2D model predictions were successfully validated with tests performed at 600 °C to 2000 °C final temperature, with 10 and 50 °C/s heating rates. The evolution of the final products and mass losses of pyrolyzed biomass are enhanced with temperature and heating rate. Moreover, the higher the temperature and heating rate, the higher the gas yield. This emphasizes the intra-particle tar secondary reaction into gas for pyrolysis of large size sample under high temperature and heating rate.

1. Introduction

Sustainable heat and power generation from renewable energy sources such as biomass and solar attract more and more attention owing to the continuous diminution of fossil fuels and the intensifying environmental problems. Between 2010 and 2040 significant developments in renewable energy production are expected in biomass energy (from 45217.4 to 136950.2 PJ) and solar energy (from 184.2 to 55768.2 PJ) [1].

5. Conclusions

Solar pyrolysis characteristics of beech wood under different temperatures and heating rates were investigated theoretically by CFD modeling, and simulation results were compared with experimental data obtained with a 2 kW vertical solar furnace. The 2D unsteady numerical model predictions are in good agreement with the experimental results. The evolution of the final products and mass losses of pyrolyzed biomass are enhanced with temperature and heating rate. Moreover, the higher the temperature and heating rate, the higher the gas yield. This emphasizes the intra-particle tar secondary reaction into gas for pyrolysis of large size sample under high temperature and heating rate. Pseudo-stoichiometric coefficients about the mass fraction of primary tar converted by the reaction to gas and secondary tar were determined at different temperatures and heating rates for the first time.