Abstract

This paper deals with the design, construction, and experimental verification of a high-force-density, tubular, linear, and permanent-magnet motor driven from a high-power-density matrix converter for an aerospace application. This paper also describes the implementation and experimental verification of a novel thermal management technique for the phase windings of electrical machines. The technique introduces a higher thermal conductivity path between the center of the slot and the cooling arrangement, thus increasing the heat flow away from the slot center. An introduction to the design of the motor is first given, after which an introduction to the technique is presented. A study of how the implementation of the technique affects motor performance is then presented. A detailed overview of the construction aspects is highlighted, and finally, experimental validation is used to illustrate the comparison between the predicted results and the measured results, obtained from an instrumented test rig.

I. INTRODUCTION

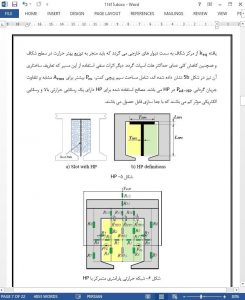

HIGH performance electrical drive applications such as those for the aerospace industry often require the electrical machine designer to push the boundaries in terms of size, efficiency and reliability through all the design stages. The drive towards the more electric aircraft (MEA) [1, 2] seeks to reduce or remove the presence of traditional, hydraulic, pneumatic and mechanical systems from aircraft. This makes the performance of electrical machines in terms of the torque/force density, fault tolerance and reliability, doubly important [3].

VIII. CONCLUSION

Considering the nature and the design requirements of the TLPM motor, then from the above the most critical output parameter of the motor is of course its force capability and its ability to withstand the requirement both thermally and electro-magnetically. The capability of the machine to satisfy the requirements from both perspectives can easily be observed in Fig. 22 and Fig. 23.

The experimentally measured, performance capability of the TLPM motor is presented and compared to the predicted capability in tabulated form in Table III.