Abstract

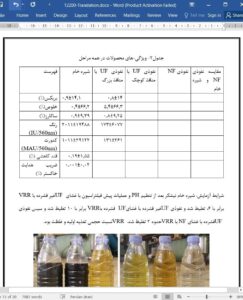

Application of membrane filtration to sugarcane juice refining is appealing because it can eliminate the usage of chemicals, achieve continuous and automated production, as well as produce superior quality of juice. However, some technical problems, such as low permeate flux, high sucrose loss in membrane retentate and serious membrane fouling, are impeding this technological upgrading in sugar industry. In this work, an integrated membrane process consisting of a tubular loose ultrafiltration (UF), a spiral-wound tight UF and a spiral-wound NF was developed to refine the raw sugarcane juice at pilot-plant scale. With a super high volume reduction ratio (VRR) of 20, the loose UF was able to be operated at a flux from 30 to 70 L m−2 h−1, and the tight UF could run at a flux from 10 to 40 L m−2 h−1; at the same time, the color removal kept more than 95%. Moreover, diafiltration operation could recover most of sugar in the UF concentrates, leading to a high sucrose recovery of up to 98% in two-stage UF. A novel cascade diafiltration mode was proposed to save water by 25% compared with the separated diafiltration. Mathematical models could well predict the diafiltration efficiency for the loose UF but not for the tight UF. Permeate flux of the loose UF was dominated by membrane fouling while for the tight UF, osmotic pressure played a more important role in the flux decline. With a suitable cleaning strategy, the performance of this integrated membrane process can be nearly regenerated although the temperature jump between filtration and cleaning (60–30 °C) might result in some foulants accumulating in the membrane system. These results would serve as a valuable guide for process design and practical operation in subsequent industrial application.

4. Conclusions

This work demonstrated that an integrated membrane process (two-stage UF followed by NF) could accomplish clarification, decoloration, and pre-concentration of raw sugarcane juice at pilot-plant scale. The color and turbidity removals were up to 96.55% and 99.99%, respectively, and the color value of the final product was below 800 IU, which could be used to produce the superior white sugar by subsequent multi-effect evaporation and crystallization. Diafiltration was carried out to recover the residual sucrose in the UF concentrates, and CVD mode outperformed dilution-concentration mode because the former enabled continuous operation and reduced water consumption. Compared with separated CVD, a novel cascade diafiltration was able to further save water by 25%. Based on mass balance and retention equations, mathematical models were developed for predicting the sucrose recovery efficiency by different diafiltration processes. The simulation results agreed very well with the experimental data for the loose UF but not for the tight UF, as the sucrose retention was increasing during the diafiltration by the tight UF.

For the tubular loose UF, both membrane fouling and viscosity increase might be responsible for the flux decline, while for the spiral-wound tight UF, since the high operation temperature (60 °C) amplified the osmotic pressure effect, osmotic pressure played an important role in its flux variation. A combined strategy with cleaning agent followed by NaClO could almost fully recovered the membrane permeability of the loose UF membrane, while a single cleaning agent enabled to thoroughly recover the permeabilities of the tight UF and NF membranes. However, due to the temperature jump between filtration and cleaning (60–30 °C), there were still some foulants accumulating in the membrane pores, leading to a permeate flux decay in the first several days. With regular chemical cleaning once a day, this integrated membrane process could be operated stably at pilot-plant scale for 45 days, which is promising to be industrialized.