Abstract

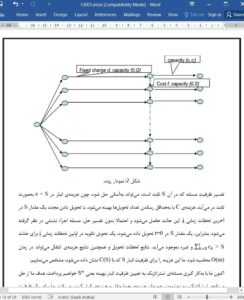

This paper deals with the optimization of the flow of sterile instruments in hospitals which takes place between the sterilization department and the operating theatre. This topic is especially of interest in view of the current attempts of hospitals to cut cost by outsourcing sterilization tasks. Oftentimes, outsourcing implies placing the sterilization unit at a larger distance, hence introducing a longer logistic loop, which may result in lower instrument availability, and higher cost. This paper discusses the optimization problems that have to be solved when redesigning processes so as to improve material availability and reduce cost. We consider changing the logistic management principles, use of visibility information, and optimizing the composition of the nets of sterile materials.

1 Introduction

The cost of health care in developed countries is around 10% [2] of gross domestic product and is expected to increase. Hence, health care cost places an increasingly heavy burden on national and individual budgets, and many developed countries are implementing policies to (stimulate health care providers to) cut cost.

6 Concluding remarks

Redesigning the sterile logistics processes can increase effectiveness of hospitals, as it is widely sought. The results and examples in this paper indicate that significant cost reductions are possible when making appropriate use of logistic principles, operations research methods, and IT (such as RFID).