Abstract

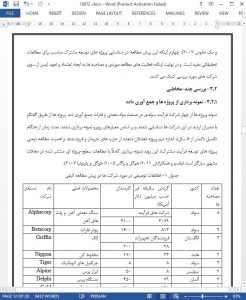

Process development is key to competitiveness in process industries. However, budget overruns frequently plague process development projects which span organizational boundaries to involve both buyers and suppliers. We identify uncertainty and equivocality as key antecedents causing such negative effects, and investigate the reduction and performance implications of these two variables. An empirical survey of 52 joint process development projects show that project teams reduce uncertainty through early end-user involvement, whereas equivocality can be reduced by joint problem-solving activities among buyers and suppliers.

1. Introduction

Process development is regarded as a key for competitiveness in process industries and in other manufacturing industries, because it increases production yields, cuts costs, and allows firms to contend with competition (Aylen, 2013; Pisano, 1997; Robertson et al., 2009; van Rooij, 2005). Process development involves developing and implementing new or significantly improved process technology and machinery equipment (OECD, 2005). Process development projects are typically large, in terms of both time and money, entailing significant management challenges (Scott-Young and Samson, 2008). Indeed, a recent study by Ernst and Young (2011) found that process development projects within the metals and minerals industries (the industry on which the present study focuses) are commonly plagued by budget overruns of 70% or more. Consequently, developing and implementing new process technology is a necessary but risky endeavor that may seriously endanger long-term competitive advantages and the financial viability of firms if not managed proficiently (Filippou and King, 2011).

5.3. Limitations and outlook

Despite our comprehensive data collection process, consisting of a qualitative pre-study and 251 survey respondents, the total sample for the present study was limited to 52 projects conducted by four Swedish process firms and their equipment suppliers. The nonrandom sample and limited sample size of the present study limit the potential to make generalizations to a larger population beyond the scope of the present study. In particular, our cross sectional research design can only imply, rather than prove, causality. To this end, an even larger sample and longitudinal research design with data collection over several years, as well as in other cultural settings (e.g., North America, Asia), would be beneficial for future research.