Introduction

A major bicycle manufacturer establishes an automated warehouse for incoming components. Robots glide up and down the high-rise bays, selecting bins of components under computer control; the bins are passed on to a conveyor system; they move around on a path determined by barcode scanners that identify each bin and route it to a stock picker. The stock picker removes items for despatch to the factory floor as instructed by a computer workstation. An automated guided vehicle rolls off to the factory along a track painted on the floor.

Establishing such a system would cost several millions of dollars. However, the expected efficiency of this system has not yet been observed as a result of difficulties encountered with the quality insurance programme for incoming components, and bottlenecks in the successive operations. A manually operated inventory system might do as well or even better.

Conclusion

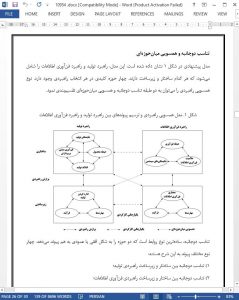

A strategic alignment model has been developed in this study for a manufacturing information system that specifically addresses the requirements of leveraging the emerging developments in information technologies. This model is based on the requirement to achieve alignment across structural and infrastructural domains as well as functional integration across manufacturing and IT areas. This model provides an evolutionary process with four different stages which leads towards the goal of a world-class manufacturer. From a research perspective, this model can be used to describe and categorize the emerging examples of exploiting IT as a lever for BPR. From a management decision-making perspective, this model serves the purpose of identifying the different alternatives to leverage IT for BPR.