Abstract

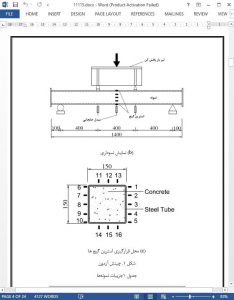

To study the mechanical behavior of high-strength concrete filled high-strength square steel tube (HCFHST) under pure bending load, six specimens with different steel ratio were tested. The corresponding nonlinear finite-element models were established to analyze the mechanical properties. The load-displacement curves obtained from the numerical analyses are consistent with the experimental results. In addition, the influences of different materials are analyzed in this paper. The moment-curvature relationship can be divided into three stages: elastic stage, yield stage and hardening stage. And the ultimate bearing capacity increased with the steel ratio, steel yield strength and concrete compressive strength. Moreover, the ultimate bearing capacity of the experiment and finite-element analysis (FEA) model is compared with the requirements of codes: AISC-LRFD (1999), AIJ (1997), EC4 (1994) and GB50936-2014 (2014). The test and FEA result were the most compatible to the calculated result of EC4 (1994). And find the results in this paper is the most compatible to the code EC4 (1994).

1. Introduction

Compared with traditional reinforced concrete structure, concrete filled steel tube (CFST) has a higher bearing capacity, ductility and fire resistant capacity. Besides, it's also an economic structure type and can be constructed easily. Because of these characteristics, it has been widely used in practical engineering such as high-rise buildings and longspan bridges. The modern building has a higher demand for the construction height and span length. Therefore, the structure design becomes more ponderous. High-strength concrete filled high-strength square steel tube (HCFHST), which takes the advantage of both highstrength concrete and high-strength square steel tube can raise the ultimate bearing capacity and decrease the weight of the structure.

6. Conclusions

Based on the analysis and discussion on the test and FEA results, the following conclusions can be drawn:

(1) The HCFHST specimen under pure bending load has a high ductility. The deflection curve performs close to sinusoid shape, and it fails because of the local bulking of the top surface of the steel tube at mid-span.

(2) The moment-curvature relationship of the HCFHST specimen under pure bending load can be separated into four stages according to the mechanical behavior of the components: elastic stage, yield stage and hardening stage.

(3) Before concrete crack, core concrete mainly resists the bending moment. After that the proportion of steel tube increases, and after tensile steel yields, steel tube mainly resists the bending moment.

(4) The ultimate bearing capacity of the HCFHST under pure bending moment significant increases with steel ratio and steel yield strength. The increase due to the core concrete compressive strength is much less than the other two design variables.