Abstract

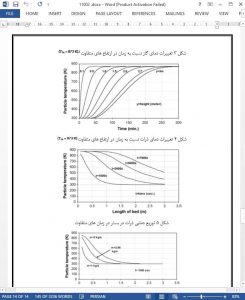

Energy consumption and production capacity are two major concerns in the steel making industries which are using electric arc furnace (EAF). To improve the performance of EAF, a new initiative technique has been introduced in which sponge iron particles are preheated before entering the furnace. A heat exchanger is used to transfer waste energy from EAF flue gas to a neutral gas like nitrogen, which in turn preheats the sponge iron particles in the fixed bed. The method has several desirable advantages including electric energy saving, increasing the productivity and reduction in electrode and refractory consumption. In order to estimate the extent of energy saving and productivity increase, the preheating process was simulated in the bed. The thermal characteristics of the fixed bed were predicted by a numerical solution of differential equations for granular sponge iron and heating gas. The temperature of sponge iron particles and heating gas were also predicted in different layers of the bed and at different times. Based on the simulation results it is found that the energy consumption in the EAF can be reduced up to 14% and productivity can be increased up to 13%.

1. Introduction

The iron and steel industry is the largest industrial energy consumer. According to Camdali et al. (2003), approximately 12% of the world energy production is used in the iron and steel section. Bisio et al. (2000) reported that after the employee costs, energy costs (about 30% of the total cost) represent the second highest cost element in integrated steel works. The share of the electric arc furnace (EAF) technology in the iron and steel industry is increasing rapidly and is estimated for at least 50% of the total steel production in 2010 based on the prediction of Raja et al. (2005). Future growth in EAF steelmaking depends on continued improvements in energy use, operating costs, and furnace productivity. It is a well-known fact that over 20% of the energy generated in EAF is left in the form of off-take gases. Melting of iron by EAF is a very energy consuming process in which temperature of sponge iron particles is raised from ambient temperature up to 1500 ◦C. Since electrical energy which is the most expensive form of energy used in EAF, lowering the energy consumption is a major concern in these industries.

8. Conclusion

There is huge amount of energy and exergy wasted in EAF industry which can be reused by application of proper scheme. Preheating the sponge iron particles is one of the feasible schemes which could be applied in order to decrease energy consumption and increase productivity. In this scheme, flue gas energy is transferred to a neutral gas through a heat exchanger and then the hot gas is used to preheat the sponge iron particles held in the silo. Simulation of preheating process shows that using this technique electrical energy can be saved up to 14% and furnace productivity can be increased up to 13%. There is good potential to further increase in saving by increasing the inlet gas temperature.