Abstract

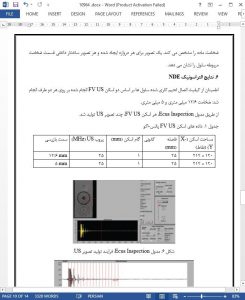

Ultrasonic non-destructive methods have demonstrated great potential for the detection of flaws in a material under examination. In particular, discontinuities produced by welding, brazing, and soldering are regularly inspected through ultrasonic techniques. In this paper, an advanced ultrasonic non-destructive evaluation technique is applied for the quality control of brazed copper cells in order to realize an accelerometer prototype for cancer proton therapy. The cells are composed of two half-plates, made of high conductivity 99.99% pure copper, brazed one on top of the other. Full volume ultrasonic scanning based on the pulse-echo immersion testing method were carried out to allow for the ultrasonic 2.5 D axial tomography of the cell, realizing the quality assessment of the brazing process.

1. Introduction

Brazing is a key technology in the production of components made of high performance materials. The brazing process joins two pieces of metal or alloy together through a third, molten filler metal or alloy. The joint area is heated above the melting point of the filler metal or alloy but below the melting point of the base metals or alloys to be joined. The molten filler metal or alloy flows into the gap between the two metal pieces by capillary action and forms a strong metallurgical bond as it cools down to solidification. Brazed joints have high tensile strength, typically higher than the strength of the utilized filler metal or alloy [1].

7. Conclusions

An advanced ultrasonic NDE technique based on the FV US scanning technique was applied for the quality control of brazed copper cells of an accelerometer prototype utilized for radionuclide production and proton therapy use. The quality of the brazing process is critical for the functionality of the prototype that does not contain any continuity solution in its structure in order to guarantee the homogeneity of the generated magnetic field responsible for protons acceleration. The back-to-back cell consist of two half-cell plates, made of high conductivity OHFC 99.99% copper, brazed one on top of the other.