Abstract

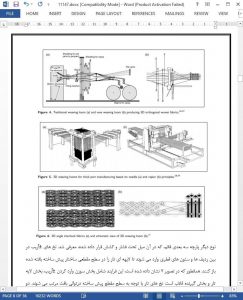

The aim of this study is to review three-dimensional (3D) fabrics and a critical review is especially provided on the development of multiaxis 3D woven preform structures and techniques. 3D preforms are classified based on various parameters depending on the fiber sets, fiber orientation and interlacements, and micro–meso unit cells and macro geometry. Biaxial and triaxial two-dimensional (2D) fabrics have been widely used as structural composite parts in various technical areas. However, they suffer delamination between their layers due to the lack of fibers. 3D woven fabrics have multiple layers and no delamination due to the presence of Z-fibers. However, the 3D woven fabrics have low in-plane properties. Multiaxis 3D knitted fabrics have no delamination and their in-plane properties are enhanced due to the bias yarn layers. However, they have limitations regarding multiple layering and layer sequences. Multiaxis 3D woven fabrics have multiple layers and no delamination due to Z-fibers and in-plane properties enhanced due to the bias yarn layers. Also, the layer sequence can be arranged based on end-use requirements. However, the multiaxis 3D weaving technique is at an early stage of development and needs to be fully automated. This will be a future technological challenge in the area of multiaxis 3D weaving.

Introduction

Textile structural composites are widely used in various industrial sectors, such as civil and defense as they possess some improved specific properties compared to basic materials such as metal and ceramics.16 Research conducted on textile structural composites has shown that they can be considered as alternative materials since they are delamination-free and damage tolerant.3,7 Two-dimensional (2D) biaxial, triaxial and three-dimensional (3D) fabric structures are used as structural elements in medical, space and rocket propulsions and transportation industries.8 Examples of these elements are plate, stiffened panels, beams and spars, shell or skin structures, hip and medical devices and prostheses.911 Recently, it has been found that using nano-based high modulus fibers in 3D fabrics results in a 10-fold increase of their mechanical properties.12

Conclusion

In this study, 3D fabrics, methods and techniques were reviewed. Biaxial 2D fabrics have been widely used as structural composite parts in various technical areas. However, composite structures of biaxial 2D fabrics suffer delamination between their layers due to the lack of fibers. Biaxial methods and techniques are well developed. Triaxial fabrics have delamination, an open structure and low fabric volume fractions. However, the in-plane properties of the triaxial fabrics become homogeneous due to the bias yarn orientations. Triaxial weaving methods and techniques are also well developed. 3D woven fabrics have multiple layers and no delamination due to the presence of Z-fibers. However, 3D woven fabrics have low inplane properties. 3D weaving methods and techniques are commercially available. Multiaxis 3D knitted fabrics, which have four layers and layering achieved by stitching, have no delamination and their in-plane properties are enhanced due to the bias yarn layers. However, it has limitations regarding multiple layering and layer sequences. Multiaxis 3D knitting methods and techniques have been perfected. Multiaxis 3D woven fabrics have multiple layers and no delamination due to Z-fibers and enhanced in-plane properties due to the bias yarn layers. Also, the layer sequence can be arranged based on end-use requirements. However, the multiaxis 3D weaving technique is at an early stage of development and needs to be fully automated. This will be a future technological challenge in the area of multiaxis 3D weaving.