Abstract

Application of different alternatives for increasing the reaction furnace temperature of Claus sulfur recovery units (SRUs) are investigated by chemical equilibrium calculations. The Gibbs free minimization method based on Lagrangian multipliers is used for formulating the problem. The usefulness of different techniques such as fuel gas spiking, indirect air and/or acid gas preheating, oxygen enrichment, acid gas enrichment and direct air preheating for increasing the furnace temperature are determined by the proposed algorithm. In the case of lean feed acid gases, it may be necessary to use a combination of methods in order to attain the minimum furnace temperature required for flame stability and complete destruction of acid gas hydrocarbon contaminants. It is found that the acid gas enrichment is a reliable technique for providing the required reaction furnace temperature when a high flow of too lean acid gas is to be processed in a Claus unit. The predicted reaction furnace temperatures are in good agreement with the measured experimental values.

1. Introduction

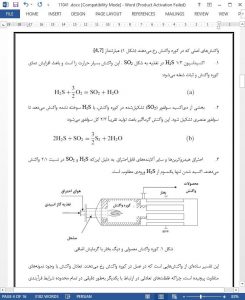

The Claus process continues to be the most widely used process worldwide for the production of elemental sulfur from gaseous hydrogen sulfide [1]. The requirements to be met by Claus plants are dictated by the operating conditions of modern refineries and natural gas plants and increasingly stringent emission control regulations.

Several variations of the basic Claus process have been developed to handle a wide range of feed gas compositions [1,7,12]. Straight-through operation results in the highest overall sulfur recovery efficiency and is chosen whenever feasible. Air is supplied by blower and the combustion is carried out at 1–2 bar, depending on whether or not a tail gas treatment unit is installed downstream of the Claus plant.

9. Conclusions

Many Claus sulfur recovery units suffer from poor flame stability and hydrocarbon destruction in the reaction furnace due to a low reaction furnace flame temperature. This is normally a symptom of poor acid gas feed quality. In order to mitigate this problem, several commercially viable techniques available for increasing the furnace temperature such as fuel gas spiking, air and acid gas preheating, direct fuel gas air preheating, oxygen enrichment and acid gas enrichment are evaluated by chemical equilibrium calculations. The Gibbs free minimization method is used for simultaneous prediction of reaction furnace temperature and optimum air flow rate of Claus sulfur recovery units at different operating conditions and the predicted results are compared with experimental data.