Abstract

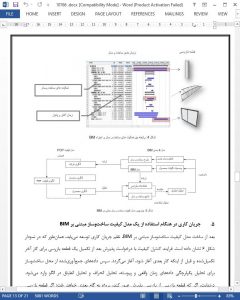

The potential of Building Information Modeling (BIM) to support a transformation of the processes of design and construction has been evident in the construction industry. Although BIM is considered helpful in improving design quality by eliminating conflicts and reducing rework, there has been little research into using BIM throughout the project for construction quality control and efficient information utilization. Due to the consistency of design data with quality data and construction process with quality control process, the potential of BIM implementation in quality management lies in its ability to present multi-dimensional data including design data and time sequence. This paper explores and discusses the advantages of 4D BIM for a quality application based on construction codes, by constructing the model in a product, organization and process (POP) data definition structure. A case study is provided to validate the use of the proposed 4D BIM application for quality control during the construction phase of the Wuhan International EXPO Center.

1. Introduction

The quality of a product is reflected in its ability to satisfy stated or implied needs and internal characteristics of a finished product in addition to its external design [1]. Therefore, construction product quality can be defined as: the degree to which the stated or implied needs and the internal characteristics are guaranteed during the process of construction [2]. This research defines quality as compliance with construction codes and specifications.

7. Conclusions and recommendations

The presented findings contribute to the understanding of the potential use of BIM in construction quality management and fill an existing gap in the knowledge on the use of BIM for construction quality management. This paper explored the implementation of BIM in quality management and proposed integrated solutions to improve current quality management processes with assistance of a BIM working environment. A BIM-based quality model has been proposed to combine BIM and the existing quality POP model. Also this paper discusses how these two models will work together to facilitate construction quality management. It helps the project participants to better understand the quality progress and to collaborate more effectively thanks to a visualized data format.

The key benefits of the construction quality model proposed in this paper lie in the following aspects: First, the utilization of design information ensures information consistency and facilitates quality management process. Second, the fully standardized and structured construction codes are integrated in the model to provide clear construction task requirements for instruction and verification. Typical errors caused by misunderstanding of cross-reference codes can be avoided. Third, 4D application ensures the timely inspection and virtualization of the whole process, which helps the project participants to better understand the quality requirements acceptance, and to collaborate in a visualized manner.