Abstract

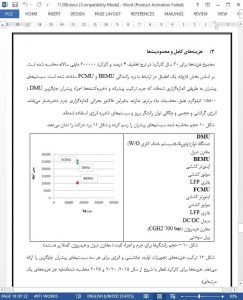

This paper discusses alternative propulsion systems for heavy railway vehicles. First, edge conditions such as drivers and roadblocks for the implementation of alternative propulsions in railway vehicles are discussed. For operations on a non-electrified railway route, the required main propulsion components of a battery electric multiple unit and of a fuel cell multiple unit are roughly dimensioned and economically compared with a benchmark diesel multiple unit, the BR 612 of Deutsche Bahn. The non-electrified route from Ulm to Oberstdorf was considered as a reference route for the simulation and drivetrain layout. Our analysis finds that alternative drive concepts hold a high potential for future railway vehicles, depending on the boundary conditions.

I. INTRODUCTION

Although electrified vehicles have been in use in railway applications for over 100 years, vehicles with energy-independent, diesel based drives are still of a great importance for the world’s railway networks. As of today, only 51 % of heavy mainline railways in Europe are electrified. In Asia (< 35 %), Africa (< 16 %) and in America (< 1 %), the rate is even lower [1]. Capital intensive overhead electrification is done primarily on routes with a high degree of track utilization, as it may not prove economically viable in case of low line utilization. Moreover, increasing fuel prices and stricter emission regulations pose a challenge for railway operators that rely on diesel propulsion today and may direct their attention towards alternative propulsion systems in the future.

V. CONCLUSIONS AND FUTURE WORK

The paper was aimed at reviewing the potentials of alternative propulsion systems in railways technically and economically. As alternatives to DMUs, both BEMUs und FCMUs were evaluated in case continuous trackside electrification does not pay out economically. On the non-electrified reference railway route Ulm to Oberstdorf, relevant drivetrain and energy storage components of BEMU and FCMU were dimensioned and evaluated in terms of their propulsion related investment and replacement costs as well as the fuel costs over a vehicle’s operational life.